A bearing where two surfaces move in relation to one another without the benefit of rolling contact is referred to as a slide bearing. Slide bearings are a particular kind of linear slide, which are mechanisms for linear motion that allow for free motion in one direction. A lubricant can facilitate the motion of two surfaces sliding over one another. The lubricant is squeezed by the motion of the components and can produce enough pressure to separate the surfaces, decreasing frictional contact and wear. Slide bearings frequently take the place of other systems, such as ball or roller bearing systems. Read More…

With a multitude of bearing and slide designs available, both standard and custom designed models, Del-Tron Precision Inc. is proud to be a one-stop shopping experience for customers with linear motion needs.

TUSK Direct is a company that produces high quality linear motion components such as linear bearings as well as assemblies for automated equipment.

Isotech is a distributor of precision linear motion components -- crossed roller linear bearings, ball slide assemblies, crossed roller slide tables, motorized tables, position stages and more.

More Slide Bearing Manufacturers

Types of Slide Bearings

Slide bearings, also known as plain bearings, are essential components in a wide array of industrial and engineering applications. They reduce friction between two moving parts by providing a smooth sliding interface, supporting radial or axial loads in machinery. Selecting the right type of slide bearing is crucial for optimizing performance, longevity, and efficiency in mechanical systems. Understanding the varieties of slide bearings—classified by load direction and material—helps engineers and buyers make informed decisions tailored to specific operating environments, budgetary constraints, and maintenance requirements.

Slide bearings can be categorized according to the bearing load direction. This categorization divides sliding bearings into two types: axial thrust sliding bearings and radial sliding bearings. The material of the shaft also determines how they are categorized. Bronze bearings, cast iron bearings, plastic bearings, jewel bearings, carbon bearings, and more are several types of slide bearings that serve diverse applications and industries.

Type Based on Bearing Load Direction

Choosing a slide bearing by load direction is fundamental to ensuring optimal mechanical performance. Load direction determines whether a bearing must support forces radially (perpendicular to shaft) or axially (parallel to shaft). Understanding this distinction is key when designing or specifying components for manufacturing, automotive, aerospace, or heavy equipment applications.

Radial or Journal Bearings

In radial bearings (also known as journal bearings), the load operates perpendicular to the direction of motion of the moving member. These bearings are widely used in rotating machinery, such as electric motors, turbines, pumps, compressors, and automotive engines. They are designed to support the rotating shaft and minimize friction, ensuring smooth and efficient operation. Radial slide bearings are ideal where high rotational speeds and moderate loads are present, and they can be manufactured from various materials depending on the application's lubrication, temperature, and load requirements.

Common use cases: Electric motors, generators, pumps, fans, and internal combustion engines.

Questions to consider: How do journal bearings improve efficiency in rotating machinery? What are the best materials for journal bearings in high-speed applications?

Axial or Thrust Bearings

A specific kind of rotary rolling-element bearing is a thrust bearing. Axial bearings permit rotation between parts like other bearings, but they are made to support mostly axial loads, i.e., loads that are parallel to the axis of the shaft. These bearings are commonly found in automotive transmissions, machine tool spindles, marine propeller shafts, and heavy-duty industrial applications where axial forces are significant. Thrust bearings can be designed for either low or high-speed operations and are selected based on load, speed, and environmental factors.

Common use cases: Automotive gearboxes, marine propulsion, heavy machinery, and rotary tables.

Action-driven search prompt: Looking for the best thrust bearings for high-load axial applications? Compare leading manufacturers and material options.

Type Based on Material

The choice of material significantly impacts the performance, durability, and maintenance requirements of slide bearings. Manufacturers offer a variety of options to address diverse industrial needs, environmental conditions, and budget considerations. Below are the most common material categories used in slide bearing manufacturing:

Carbon Insert Bearings

Graphite is employed as a shaft lubricant when the environment is too abrasive for rolling-element bearings. In carbon insert bearings, the cast bronze used in the conventional design is machined to the bearing's specifications, and holes are drilled through the casting's outer surface and into its inner surface. The holes are subsequently filled with graphite plugs, resulting in a self-lubricating surface ideal for dry or high-temperature operations.

Sintered bronze with steel backings and graphite impregnation are some variations that allow for both dry and self-lubricated operation. High-temperature environments, such as industrial ovens, furnaces, and steel mills, frequently employ graphite bearings due to their resistance to extreme heat and corrosive atmospheres. These bearings are also valued for their low maintenance requirements and ability to operate without external lubrication.

Key benefits: Excellent performance in high-temperature, dry, or abrasive environments; self-lubrication for reduced maintenance; corrosion resistance.

How to choose: When should you opt for a carbon insert bearing over traditional metal or polymer designs?

Composite Slide Bearings

A material composed of various components, including material categories for bonding and strengthening, is used to make composite sliding bearings. Finely woven fibers impregnated with polymer resins make up composite material. The composite material's physical and chemical properties can be modified to suit specific requirements and applications, such as marine, hydraulic, and heavy industrial equipment that demand high load capacity and corrosion resistance.

These maintenance-free composite materials have an excellent load-bearing capacity, wear resistance, self-lubricating properties, and anti-corrosive behavior. This makes them the perfect choice for slide bearings in demanding movement-related applications, including bridge bearings, offshore platforms, and construction machinery.

Key advantages: High structural integrity, adaptability to custom shapes, chemical resistance, and suitability for submerged or outdoor installations.

Application tip: Composite slide bearings excel in environments where exposure to moisture, chemicals, or saltwater is frequent. Evaluate composite options when specifying bearings for bridges, piers, and marine equipment.

Plastic Slide Bearings

Compared to metal, sliding bearings manufactured of resin (commonly referred to as plastic slide bearings) are more versatile, lighter, and less expensive, making them suitable for various fields and machine parts. They feature a lower slip friction coefficient, produce less vibration and noise, and are lightweight. Their resistance to chemicals and water, combined with great plastic workability and electrical insulation, makes plastic bearings a go-to solution for food processing, packaging, medical equipment, and electronics manufacturing.

Basic plastic, engineering plastic, and high-performance plastic are some of the numerous categories of plastic that are accessible. For example, PTFE (polytetrafluoroethylene) bearings are favored for their low friction and chemical inertness, while nylon and acetal bearings offer strength and stability in moderate-load applications. Designers can use the chemical and physical qualities specifically for certain applications, such as plastic sliding bearings in conveyors, guide rails, or robotic arms.

Benefits of plastic slide bearings:

- Corrosion and chemical resistance for use in harsh environments

- Lightweight construction reduces overall system weight and inertia

- Self-lubricating options available for maintenance-free operation

- Low noise and vibration for sensitive or quiet machinery

- Cost-effective for large-scale or disposable equipment

Related search: What are the best plastic slide bearings for food industry applications? Explore FDA-approved and hygienic bearing solutions.

Polymer Bearings

The newest method to slide bearings is polymer bearings, typically coiled with lubricating strands or injection molded with solid lubricants. A thin metal shell is frequently joined with the high slip material PTFE to create a slide bearing that may operate without cold flow. These bearings' effective range can be reduced by heat; metal shells are occasionally utilized to dissipate the heat generated during operation, ensuring consistent performance in demanding settings.

Molded polymer bearings often have lubricant dispersed throughout the whole bearing body. Any of these bearings could experience swelling due to dampness, so it's important to select low moisture-absorbing materials for usage in humid or wet areas. Many manufacturers offer bearings constructed with advanced polymers—such as PEEK or UHMWPE—for usage in corrosive or sanitary environments.

For polymer bearings to function properly, the shaft's smoothness is important. It shouldn't be too smooth or too rough, as this can affect the formation of the lubricating film and overall bearing life. The compatibility of the shaft material and the bearing material is, in fact, a consideration for any fluid-film bearing to ensure optimal friction reduction and longevity.

Decision factors: Consider polymer bearings when you need lightweight, corrosion-resistant, and low-maintenance solutions for conveyors, medical devices, or cleanroom equipment.

Advantages of Slide Bearings

Slide bearings, whether used in heavy industry or precision instruments, provide a range of benefits that make them a preferred choice for many engineers and maintenance professionals. Here are the key advantages of incorporating slide bearings into your design or maintenance strategy:

- Extended Service Life: Slide bearings typically have a much longer lifespan than ball or roller bearings. This increased lifespan is even more significant when the slide bearings are made of high-performance materials such as advanced polymers, composites, or graphite alloys.

- Low Noise and Vibration: Slide bearings are significantly quieter than alternative linear motion systems that offer comparable functions. This reduced noise is due to the absence of moving or rattling metal components within the rails, leaving only the barely perceptible sound of slides sliding against one another.

- Cost Efficiency: Slide bearings are significantly more affordable than ball or roller bearings since they are built with fewer materials, last a lot longer, and are very adaptive and versatile. Their low maintenance requirements further reduce overall operating costs.

- Reduced Maintenance: With proper lubrication—whether via embedded lubricants, oil baths, or self-lubricating materials—slide bearings require less frequent service than rolling-element alternatives. This means less downtime and lower total cost of ownership in industrial facilities.

- Superior Load Distribution: Slide bearings distribute loads over a larger contact area, minimizing localized wear and extending the service life of both bearing and mating components. This makes them ideal for applications with heavy or shock loads, such as construction equipment, cranes, and presses.

- Customizability: Slide bearings can be engineered to fit virtually any shape or size, making them suitable for unique or space-constrained installations.

- Resilience in Harsh Environments: Slide bearings made from corrosion-resistant or high-temperature materials (such as graphite, PTFE, or composites) can operate reliably in challenging conditions, including chemical plants, offshore platforms, and foundries.

- Lubrication Benefits: With liquid lubrication, the sliding surface is kept apart from one another by lubricating oil to prevent direct contact, significantly reducing friction loss and surface wear. The oil coating also has some vibration-absorbing properties, further protecting mechanical systems.

Common industries and applications: Manufacturing, automation, automotive, heavy equipment, renewable energy (wind turbines, hydroelectric), marine, food processing, packaging, and more.

Still evaluating your options? Learn more about the difference between slide bearings, ball bearings, and roller bearings. Consider how your application's speed, load, environmental conditions, and maintenance requirements influence the optimal bearing choice.

Applications and Use Cases for Slide Bearings

Slide bearings are integral to a vast range of industries and applications due to their versatility, cost-effectiveness, and performance in demanding environments. Below are some of the most common sectors and scenarios where slide bearings deliver substantial value:

- Industrial Machinery: Used in presses, conveyors, injection molding machines, and packaging lines to provide reliable, low-maintenance linear and rotary motion.

- Automotive and Transportation: Essential in engines, transmissions, chassis components, and rail systems for smooth operation and vibration dampening.

- Heavy Equipment: Deployed in cranes, excavators, and earth-moving machines where shock loads and extreme conditions are routine.

- Infrastructure: Applied in bridges (bridge bearings), dams, and architectural structures to accommodate thermal expansion and structural movement.

- Marine and Offshore: Used in propeller shafts, rudder mechanisms, and offshore platforms, where corrosion resistance and maintenance-free operation are critical.

- Energy Sector: Vital for turbines, generators, and hydroelectric plants, supporting high loads and fluctuating environmental conditions.

- Medical and Food Processing: Chosen for equipment requiring hygiene, low friction, and non-contaminating materials, such as diagnostic machines and conveyor systems.

- Robotics and Automation: Enable precise, low-friction movement in automated manufacturing, pick-and-place systems, and laboratory equipment.

Need help selecting the right slide bearing for your specific application? Ask: What are the best slide bearings for high-load, low-maintenance applications in corrosive environments? Or explore our detailed guides on bearing selection by industry.

Factors to Consider When Selecting Slide Bearings

Choosing the right slide bearing involves evaluating several critical factors to ensure optimal performance, reliability, and cost-effectiveness. Here’s what buyers and engineers should assess:

- Load Capacity: Assess the maximum static and dynamic loads the bearing will encounter. Choose materials and designs rated for your application's specific requirements.

- Speed: Consider both linear and rotational speeds. Some materials (like PTFE or composites) perform better at higher speeds, while others are suited for slow, heavy-duty operations.

- Temperature Range: Match the bearing material to the application’s operating temperatures. Graphite and composite bearings excel in high-heat environments.

- Lubrication: Determine if the application can accommodate regular lubrication, or if self-lubricating or dry-running bearings are preferable for reduced maintenance.

- Environmental Conditions: Account for exposure to water, chemicals, dust, or abrasive materials. Corrosion-resistant materials are essential for marine or chemical processing industries.

- Installation Space: Evaluate available space and any dimensional constraints, as slide bearings can be customized for tight or unique fits.

- Maintenance Requirements: Consider the frequency and ease of maintenance. Maintenance-free bearings can save time and reduce operational costs.

- Cost: Balance up-front investment with expected service life and total cost of ownership. Sometimes a higher-cost, high-performance bearing provides better value over time.

Related search prompt: How do I choose between bronze, plastic, and composite slide bearings for my machinery? Compare performance, maintenance needs, and total lifecycle costs.

Choosing the Proper Slide Bearing Manufacturer

To make sure you have the most positive outcome when purchasing a slide bearing from a slide bearing manufacturer, it is important to compare at least four manufacturers using our slide bearing directory. Each slide-bearing manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each slide bearing company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple slide-bearing companies using the same message.

When evaluating potential slide bearing suppliers, consider:

- Manufacturing capabilities and customization options—Does the supplier offer custom shapes, sizes, or advanced materials?

- Industry certifications and compliance—Are their products certified for your industry (e.g., ISO, FDA, ATEX)?

- Technical support and engineering expertise—Can the manufacturer assist with design, installation, or troubleshooting?

- Delivery times and global distribution—Are lead times and logistics in line with your project schedule?

- References and case studies—Can the manufacturer provide testimonials or examples of similar successful projects?

Ready to start your search? Explore our slide bearing manufacturer directory or get in touch for personalized recommendations based on your project’s requirements.

Frequently Asked Questions About Slide Bearings:

- What are the primary differences between slide bearings and rolling-element bearings in industrial machinery?

- How do self-lubricating slide bearings reduce maintenance downtime?

- What is the best material for slide bearings in high-moisture or corrosive environments?

- How do I calculate the expected service life of a slide bearing?

- Can slide bearings be custom-engineered for unique applications or retrofits?

For more information on slide bearings, their benefits, and how to select the right bearing for your needs, explore our in-depth technical resources or contact our engineering team for expert guidance.

Air Cylinders

Air Cylinders Assembly Machinery

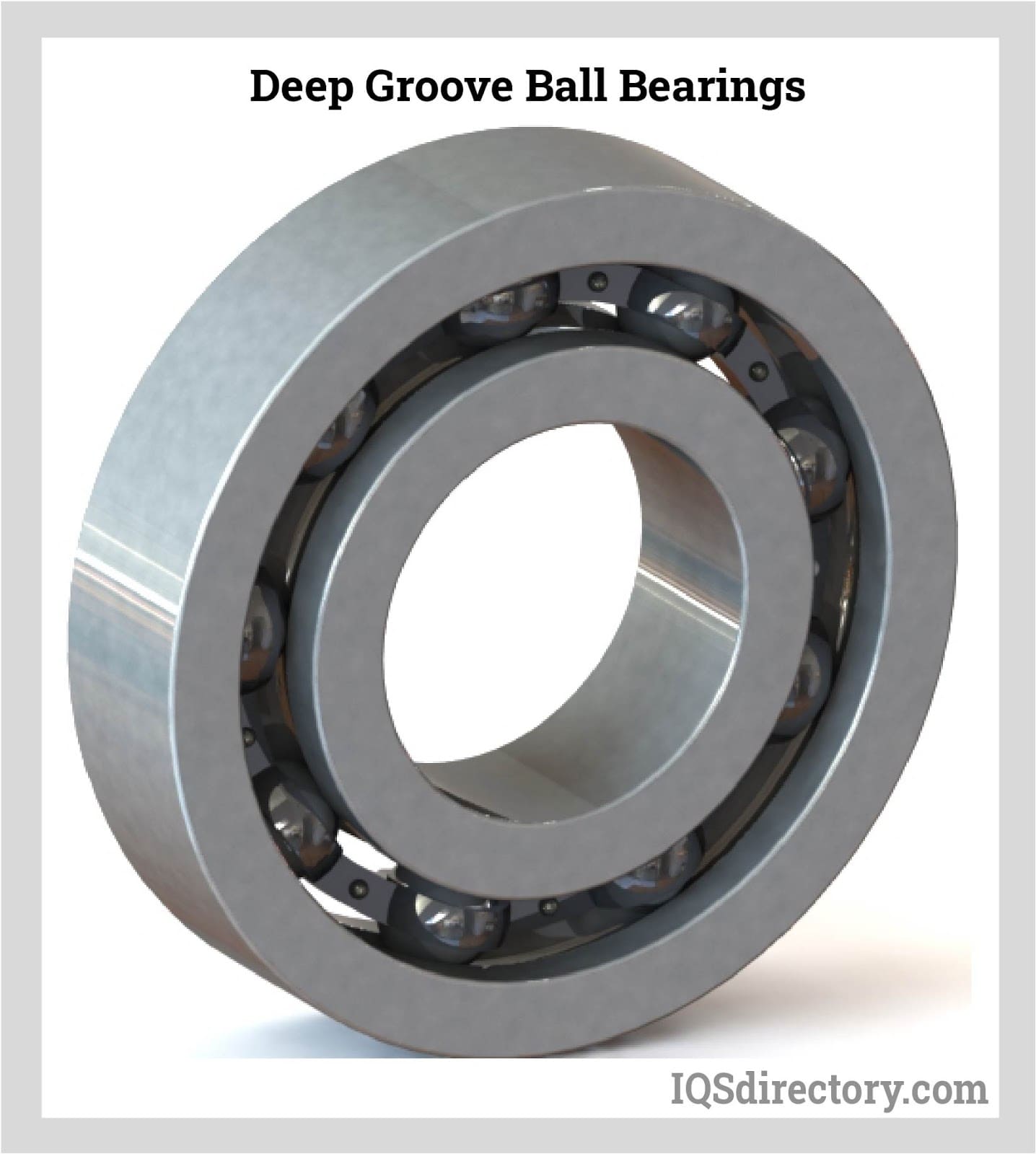

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services