Linear bearings create relative motion among parts of a machine by providing a rolling or sliding contact between the bearing and the object that the bearing is moving. Linear motion bearings are used for a variety of functions. For example, they can be found in items such as work station height adjustment mounts, and drawer glides. Read More…

With a multitude of bearing and slide designs available, both standard and custom designed models, Del-Tron Precision Inc. is proud to be a one-stop shopping experience for customers with linear motion needs.

TUSK Direct is a company that produces high quality linear motion components such as linear bearings as well as assemblies for automated equipment.

Isotech is a distributor of precision linear motion components -- crossed roller linear bearings, ball slide assemblies, crossed roller slide tables, motorized tables, position stages and more.

More Linear Bearing Manufacturers

Linear bearings are essential components in modern industrial motion control systems, seamlessly integrating with other automation solutions such as linear actuators, linear rails, and precision motion platforms to enhance performance, accuracy, and reliability across a broad range of applications. Whether in manufacturing, robotics, medical devices, or packaging automation, the right linear bearing can dramatically improve machine throughput and product quality. If you’re evaluating options for your next project, explore our comprehensive list of linear bearing manufacturers for sourcing guidance and supplier comparisons.

The term linear bearing is often used interchangeably with related phrases like linear guide, linear bushing, or linear slide, leading to some confusion within the industry. Typically, “linear bearing” refers either to the entire linear motion assembly—including the rail, carriage, and rolling or sliding elements—or, more narrowly, to just the moving part, such as the carriage with its bushings or rollers. For most practical and purchasing purposes, these terms are considered synonymous, but understanding the specifics can help ensure the right fit for your application.

A Brief History of Linear Bearing Development

Although linear bearings are often associated with 20th-century manufacturing, their roots reach back to ancient civilizations. Archaeological evidence indicates that the Greeks and Romans built primitive bearing systems to reduce friction in carts and early machine tools. During the Renaissance, visionary engineers like Leonardo da Vinci recognized the advantages of rolling motion over simple sliding, laying the groundwork for modern bearing technology.

Between 1600 and 1750, the focus in Europe shifted to refining sliding bearings, as advances in metallurgy and science allowed for more precise machining. However, the 18th century saw a resurgence in roller-type linear bearings, especially for use in wagons, carriages, and early industrial equipment. By the 19th century, the two main forms of rolling element bearings—ball bearings and roller bearings—were well established. The bicycle boom of the late 1800s accelerated the development of precision ball bearing manufacturing, setting the stage for the rise of specialized bearing manufacturers.

The transition from cast iron to steel bearings, especially during and after World War I, marked a pivotal point in the evolution of linear motion technology. Today, linear bearings are engineered for increased durability, load capacity, and operational longevity, and they are indispensable to high-speed automation, CNC machining, semiconductor manufacturing, and virtually every form of precision engineering.

Overview of Linear Bearings

Linear bearings are designed to enable smooth, precise, and low-friction movement along a predetermined path—typically a straight rail or guide. Their core function is to minimize friction between the moving element (the carriage or bushing) and the stationary rail, ensuring consistent, repeatable motion even under significant loads or high-speed cycles. The most common materials used in linear bearing construction are hardened steel (carbon or stainless), bronze, and engineered plastics such as PTFE, POM, or engineering polymers for specialized requirements like corrosion resistance or cleanroom compatibility.

Bearings are fundamental components in virtually every industry, enabling machines to move loads with high efficiency. In addition to linear bearings, other bearing types—such as radial ball bearings, thrust bearings, and roller bearings—play key roles in rotating machinery. Linear bearings, however, are purpose-built for applications where controlled, accurate, and repeatable linear movement is critical.

Linear bearings are engineered to manage a wide variety of forces, including lateral (side) loads, radial (vertical) and compressive stresses, as well as tensile and reverse radial forces. Many designs are also capable of accommodating rotational or tilting motion about the axis of travel, making them suitable for complex motion systems. It’s important to note that American and European linear bearings may differ in sizing and measurement standards—imperial versus metric—so always confirm specifications when sourcing or replacing components.

Thanks to their simplicity and cost-effectiveness, linear bearings are found in a wide range of industries and sectors:

- Manufacturing automation (CNC machines, robotic arms, pick-and-place systems)

- Medical equipment (imaging machines, lab automation, surgical robots)

- Packaging machinery (carton erectors, conveyor systems, filling machines)

- Food processing equipment (cleanroom-rated linear guides, sanitary bushings)

- Automotive assembly lines (welding robots, transfer stations)

- Aerospace and defense (precision testing equipment, flight simulators)

- Semiconductor manufacturing (wafer handling, lithography stages)

- Material handling (automated storage/retrieval systems, AGVs)

Typical use cases include automated production machinery, coordinate measurement machines (CMMs), wafer testing and handling, optical inspection, high-precision dispensing, disk validation, optical alignment, and retractable equipment such as industrial storage drawers and work surfaces.

Types of Linear Bearings

Linear bearings come in a diverse array of designs, materials, and size ranges, utilizing components like bushings, lubricants or grease, rails (round, square, or profile), rolling elements (balls, rollers, or needles), and slides. Classification terminology is sometimes inconsistent, so understanding the broad categories and their unique advantages is essential for selecting the right bearing for your application.

The two main classification criteria are:

- Type of rail: Round rail vs. square/profile rail

- Attachment method: How the moving component (carriage, bushing, or slider) connects and travels along the rail

When considering a linear guide as a complete system, the three main types are:

- Linear ball bearings (ball bushings, ball slides)

- Linear roller bearings (roller slides, needle bearings)

- Slide bearings (plain bearings, sleeve bearings, dovetail slides)

Slide bearings, also called linear plain bearings, are the most fundamental form. They operate via sliding contact—two surfaces (often made from different materials to reduce friction and direct wear to the softer component) glide against each other. Common materials include graphite, PTFE (Teflon), and oil-filled bronze. Slide bearings are commonly found in oil and gas production systems, heated pipelines, and fabrication processes involving oil, water, and steel. Their simplicity, low cost, and ability to operate in contaminated or extreme environments make them a popular choice for heavy industrial applications.

The three fundamental slide bearing configurations are:

- Boxway

- Dovetail

- Bushing (cylindrical or sleeve-type)

Bushing-type slide bearings are especially common, where the bearing travels along a round rail through a cylindrical opening. Common materials for bushings include injection-molded polymers, oil-impregnated bronze, and powdered metal alloys for specialized performance characteristics.

Rolling Element Bearings

Rolling element bearings enhance the performance of traditional slide guides by introducing rolling components (balls or rollers) between the rail and carriage, reducing friction and allowing for higher speeds, better accuracy, and lower running temperatures. As a result, they’re often preferred for high-performance automation and precision motion control applications.

There are two principal types:

- Linear ball bearings (ball bushings, ball slides): Utilize hardened steel balls to ensure smooth, low-friction movement. Variants include radial ball bearings (supporting both axial and radial loads) and thrust ball bearings (optimized for lighter thrust loads).

- Linear roller bearings: Employ cylindrical (or barrel-shaped) rollers instead of balls, providing a larger contact area and higher load capacity. Needle bearings, a subtype, use slender, needle-shaped rollers for applications with limited radial space but requiring high load support.

Linear roller bearings are valued for their mechanical simplicity, affordability, and self-cleaning action, making them the bearing of choice for machine tool beds, industrial robots, and heavy-duty automation. Their ability to handle high loads with minimal deflection is indispensable in demanding environments.

Rolling element bearings can be further divided into:

- Recirculating bearings: Rolling elements continuously circulate through the carriage, enabling full travel along the rail length. They excel in long-travel, high-duty-cycle applications and generally support higher loads.

- Non-recirculating bearings: Rolling elements are constrained within a fixed section of the rail, suited for short-stroke or limited-travel applications where compactness is crucial.

Miscellaneous Types of Bearings

Many specialized linear bearing types address unique requirements in precision engineering, automation, and scientific research. These include:

- Linear air bearings: Use a thin film of pressurized air to support the load, providing virtually frictionless motion. They are ideal for ultra-high-precision machine tools, semiconductor processing, and aerospace test equipment where contamination and vibration must be minimized.

- Linear rotary bearings: Enable simultaneous rotation and linear translation, perfect for applications requiring multi-axis motion, such as advanced manufacturing or inspection systems.

- Miniature linear bearings: Designed for compact, lightweight assemblies with high precision requirements, such as microsurgery robots, semiconductor wafer stages, and laser positioning systems.

- Precision linear bearings: Manufactured to extremely tight tolerances for applications like CNC machine tool spindles, coordinate measurement machines, and scientific research instruments.

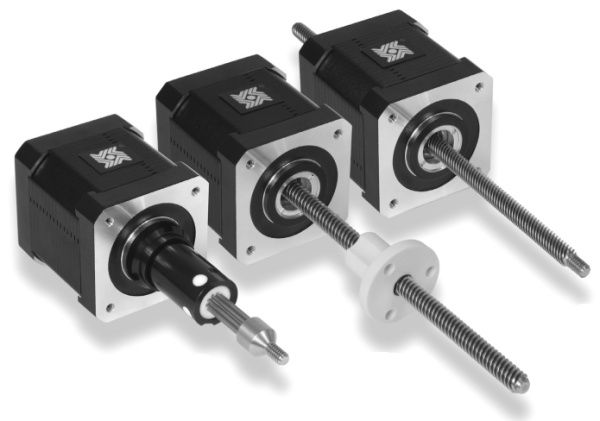

- Linear air cylinders: Typically aluminum-bodied and used in automation systems requiring precise, repeatable positioning or controlled force, such as tensile testing machines.

- Pillow block linear bearings: Enclosed in a block-style housing, these bearings are ideal for applications where the rail or shaft must move while the bearing remains stationary, such as conveyor systems or sliding doors.

- Ball spline bearings: Feature multiple recirculating ball circuits for high-torque, high-precision linear and rotary motion, commonly used in robotics, assembly automation, and high-speed packaging lines.

Other notable types and use cases include:

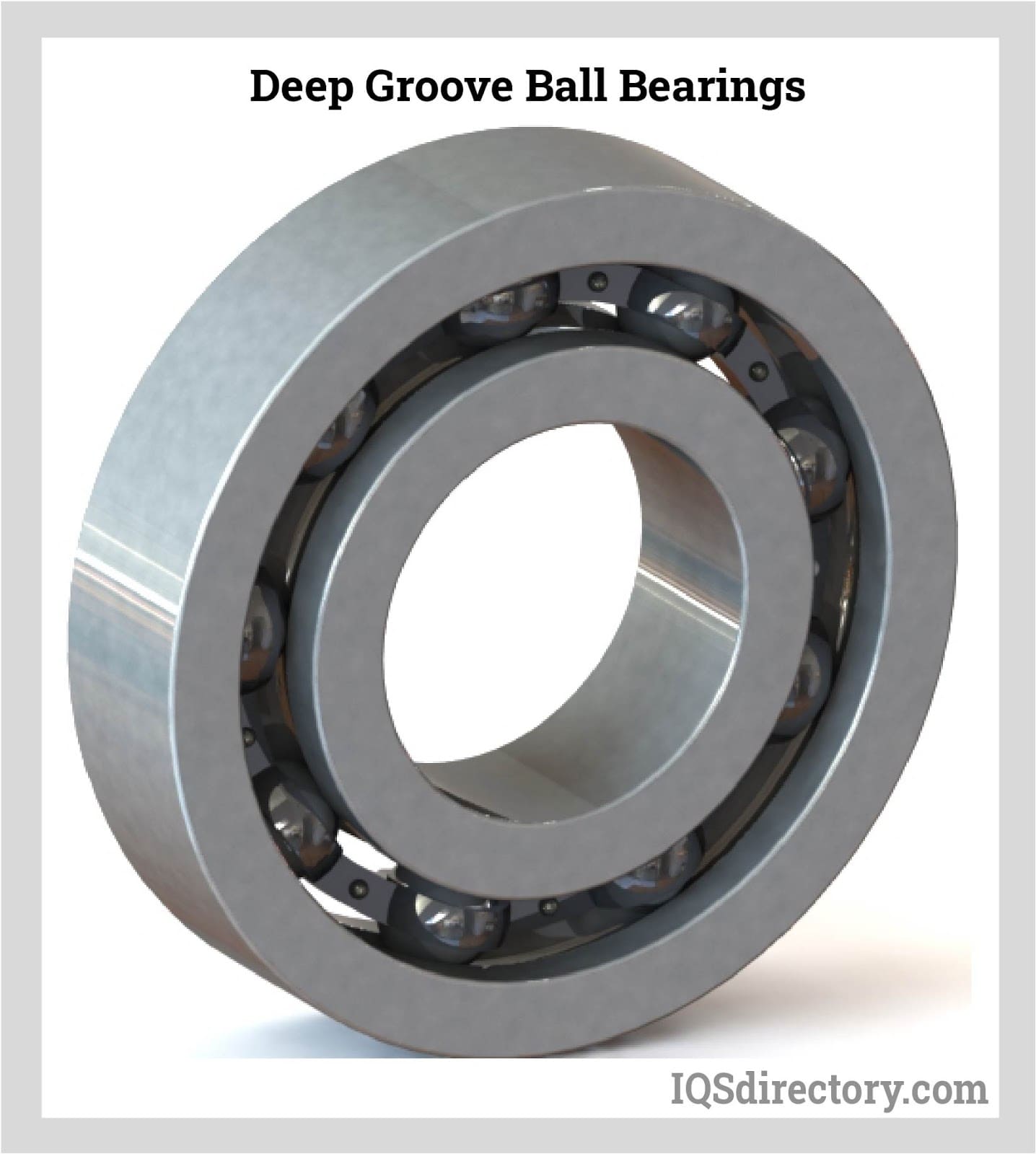

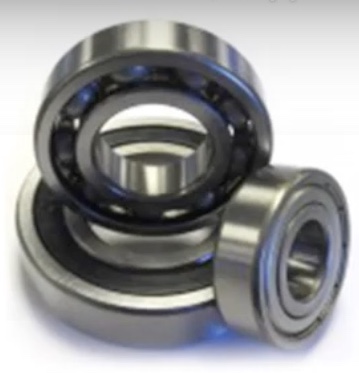

Ball Bearings

Ball bearings are perhaps the most versatile rolling-element bearings, utilizing hardened steel or ceramic balls to reduce rotational friction and support radial and axial loads. Common ball bearing types include:

- Deep-Groove Bearings (ideal for high-speed, low-torque applications)

- Thrust-Ball Bearings (suited for axial load support)

- Self-Aligning Bearings (accommodate misalignment)

- Pillow-Block Bearings (combining bearing and mount in one housing)

- Angular-Contact Ball Bearings (support combined loads and high speeds)

Each type has unique properties and is selected based on application requirements such as speed, load, alignment, and environmental factors.

Deep-Groove Ball Bearings

Deep-groove ball bearings are the default choice for high-speed, high-efficiency operations—commonly used in electric motors, pumps, and industrial fans.

Roller Bearings

Roller bearings, a broad category that includes cylindrical, tapered, and spherical rollers, are engineered for heavy-duty applications. They are crucial in oscillating or reciprocating machinery, supporting substantial radial and thrust loads while minimizing friction. Popular subtypes include:

- Tapered Roller Bearings (axle and hub support in vehicles)

- Cylindrical Roller Bearings (gearboxes, large electric motors)

- Spherical Roller Bearings (heavy industry, mining equipment)

Spherical Roller Bearings

With their robust, self-aligning design, spherical roller bearings excel in harsh environments where shock, vibration, and misalignment are common. Their durability makes them a staple in mining, construction, and heavy manufacturing industries.

Wheel-Hub Bearings

Wheel hub bearings are critical to automotive and transportation industries, supporting vehicle weight and ensuring precise, smooth wheel rotation for safety and performance.

Pillow-Block Bearings

Pillow-block bearings integrate the bearing and its housing, offering versatile mounting options and simplifying installation. Their dual-unit design makes them popular in conveyor systems, agricultural machinery, and packaging lines.

Accessories for Linear Bearings

For optimal performance and longevity, linear bearings are often combined with specialized accessories tailored to the application environment:

- Wipers: Remove dust, chips, and debris from the rail, protecting rolling elements and prolonging bearing life in contaminated or abrasive environments.

- Seals: Retain lubricants within the bearing assembly and block the ingress of contaminants, crucial for high-speed, high-precision, or cleanroom applications.

- Lubrication fittings: Enable easy, consistent application of lubricants to maintain optimal friction and minimize wear.

- End caps and covers: Further shield the bearing internals from environmental hazards.

Maintenance for Linear Bearings

Proper maintenance is essential to maximizing linear bearing performance, reducing downtime, and ensuring long service life. The most common cause of premature bearing failure is inadequate lubrication. Depending on the type of linear bearing, maintenance can include:

- Routine lubrication: Follow manufacturer recommendations for oil or grease application intervals. Some linear bearings feature self-lubricating liners or automatic lubrication ports for convenience.

- Regular inspection: Check for signs of wear, corrosion, or contamination. Run a finger along the rail to detect roughness or dryness, and inspect carriages (especially those made from softer metals like aluminum) for indentation or deformation.

- Clean storage and handling: Store spare bearings and rails in dry, debris-free environments. Protect from shocks, impacts, or sudden temperature changes.

- Replacement of accessories: Replace worn wipers or seals as needed to prevent contamination and maintain lubrication.

Things to Consider When Selecting Linear Bearings

Choosing the optimal linear bearing for your application requires careful analysis of several critical factors. Begin by defining your project’s motion requirements and environmental conditions. Key decision factors include:

- Load capacity: Static and dynamic load ratings determine how much weight the bearing can safely support. Consider both the maximum and average loads your application will encounter.

- Travel length and stroke: How far must the bearing travel? Some designs excel at long, continuous motion; others are optimized for short, precise strokes.

- Speed and acceleration: High-speed or high-acceleration applications may require advanced rolling element bearings or specialized lubrication.

- Precision and repeatability: Determine the acceptable level of play (clearance), straightness, and accuracy required by your process.

- Environment: Factor in temperature extremes, humidity, exposure to chemicals, abrasive dust, or washdown requirements typical in food processing or medical environments.

- Mounting and integration: Consider available space, mounting orientation, and compatibility with existing equipment.

- Maintenance requirements: Decide if you need self-lubricating, maintenance-free bearings or if manual lubrication is feasible.

- Material compatibility: Stainless steel, coated rails, or engineered plastics may be necessary for corrosion resistance or cleanroom use.

- Cost and availability: Balance performance with budget and lead times. Some custom or high-precision bearings may have longer delivery schedules.

In selecting a linear guide manufacturer or supplier, evaluate their ability to customize components (such as shaft shapes or guide materials), their technical expertise, responsiveness to customer requests, and shipping or fulfillment speed. With hundreds of global and regional linear bearing manufacturers, standardization is rare—so ensure that attributes like load capacity, inside diameter, length, width, and mounting options match your system requirements. If you’re unsure, request technical consultation or sample components before committing to a large purchase.

A common user inquiry is: Should I choose round rails or square profile rails for my automation project? The answer depends on your precision requirements and installation constraints. Square (profile) rails generally offer greater accuracy and rigidity, ideal for high-precision industrial automation or CNC systems. Round rails may be more forgiving of misalignment and easier to install in retrofit projects. Choosing the correct rail type at the outset can prevent costly errors or rework later on.

Durability and operational lifespan are also critical. Linear guides are rated for both static and dynamic load capacities. The dynamic load rating, in particular, helps estimate the expected service life under continuous operation. A reputable manufacturer can refine these estimates by considering additional factors such as temperature variation, lubrication frequency, exposure to contaminants, and the potential for shocks or impacts.

Frequently Asked Questions & Next Steps

- What is the difference between linear ball bearings and linear roller bearings? Explore our in-depth comparison to learn which type is best for your application.

- Where can I find replacement parts or custom linear bearings? Browse our curated supplier listings for top-rated manufacturers and distributors.

Whether you’re designing a new automation system, upgrading an existing machine, or troubleshooting motion control issues, choosing the right linear bearing is a critical step. For more technical resources, design tools, and supplier information, visit our main Linear Bearings Resource Center or contact our engineering team for personalized assistance.

What are linear bearings and how are they used in automation systems?

Linear bearings are mechanical components designed to enable smooth, low-friction, and precise movement along a straight path. They are crucial in industrial motion control systems and are often integrated with linear actuators, rails, and precision platforms to enhance performance in applications such as manufacturing, robotics, medical devices, and packaging automation.

What are the main types of linear bearings?

The main types of linear bearings include linear ball bearings, linear roller bearings, and slide (plain) bearings. Linear ball bearings use balls for low-friction motion, roller bearings use cylindrical or needle rollers for higher load support, and slide bearings rely on sliding contact between surfaces made from materials such as bronze or polymers.

What are the key considerations when selecting a linear bearing?

Selecting a linear bearing requires evaluating factors such as load capacity, travel length, speed, precision, environmental conditions, mounting options, maintenance needs, material compatibility, and cost. Defining your application’s motion requirements and operational environment is essential for choosing the best product.

What is the difference between round rails and square profile rails?

Square (profile) rails typically offer higher accuracy and rigidity, making them ideal for precise automation or CNC applications. Round rails are more forgiving to misalignment and are often easier to install, especially in retrofit projects. The choice depends on the required precision and installation constraints of your project.

How should linear bearings be maintained for long service life?

Proper maintenance involves routine lubrication based on manufacturer guidelines, regular inspection for wear or contamination, clean storage and handling, and timely replacement of accessories like wipers or seals. Inadequate lubrication is a common cause of premature bearing failure.

What accessories are available to improve linear bearing performance?

Accessories such as wipers, seals, lubrication fittings, end caps, and covers can enhance bearing performance by protecting against contaminants, retaining lubricants, and extending service life, especially in demanding or contaminated environments.

Where can I find suppliers or manufacturers of linear bearings?

You can explore a comprehensive list of linear bearing manufacturers and suppliers to compare products and sourcing options. Evaluating their ability to provide custom solutions, technical support, and shipping capabilities is important for choosing the right partner.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services