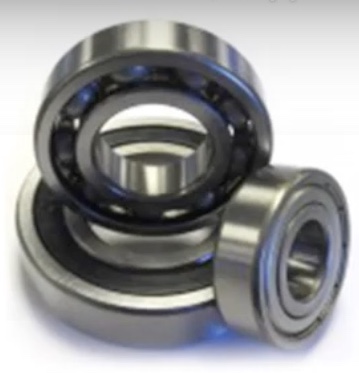

Made solely from plastic, these bearings are able to withstand the same rigors that ceramic or steel bearings can, and many manufacturers offer plastic versions of precision, miniature, linear rotary and pillow block bearings. Plastic has certain advantages over the more traditional materials, like being corrosion resistant to chemicals and acids that would harm conventional bearings. Read More...

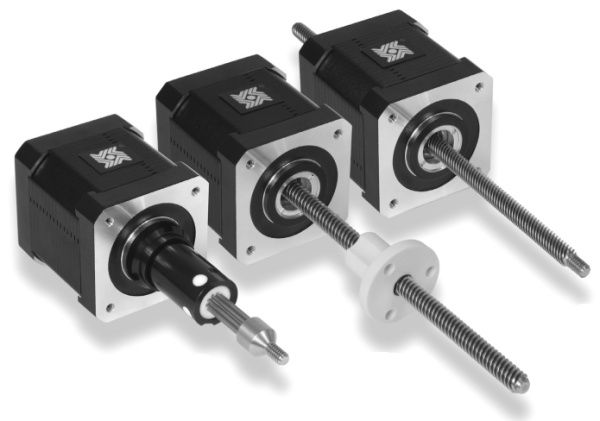

Ball & crossed roller slides, multi-axis positioning stages, motor-ready lead screw stages, air actuators, recirculating slide guides, crossed roller rail sets. Subminiature & heavy duty, straight line design & recirculating. Custom design available. Website life/load calculators CAD drawings. Our greatest strength is to offer components which provide a reliable mechanical interface for equipment.

Linear motion components, assemblies for automated equipment. Ball & crossed roller slides, linear bearings, economic linear bearings, Teflon linear bearings, multi-axis positioners, subminiature to heavy-duty, long travel available. Same-day ship, life-load calculators, CAD drawings. Call before noon & you will be working with your products the next day. We want TUSK to be the name you think of!

More Plastic Linear Bearing Manufacturers

One type of plastic linear bearings, the plastic ball bearings, are not easily nicked or scratched and will not dent their housing like metal would. Plastic is up to five times lighter than steel, which reduces the energy required to move the bearing. It is relatively inexpensive, and new designs can be made quickly by a mold tool. Magnetic distortion can be eliminated by using certain plastic ball bearings, and plastic automatically reduces noise and vibrations.

Lubrication is not necessary because the interaction of plastic and steel has a low coefficient of friction. Because of these characteristics, plastic linear bearings are used in the printing, textile, manufacturing, pharmaceutical and medical industries as well as in environments with salt water, around film processing solutions, in clean rooms, small engines, electronics and on robotic assembly lines.

Plastic linear bearings, like the variety of general linear bearings, are usually cylindrical in shape with open ends or rectangular with a carriage that runs in a V shaped groove. They are available in a variety of sizes, ranging from a few millimeters in inner diameter to centimeters according to the metric system; bearings measured in U.S. customary units are prevalent as well. There are two main categories of linear bearings, those that roll and those that slide.

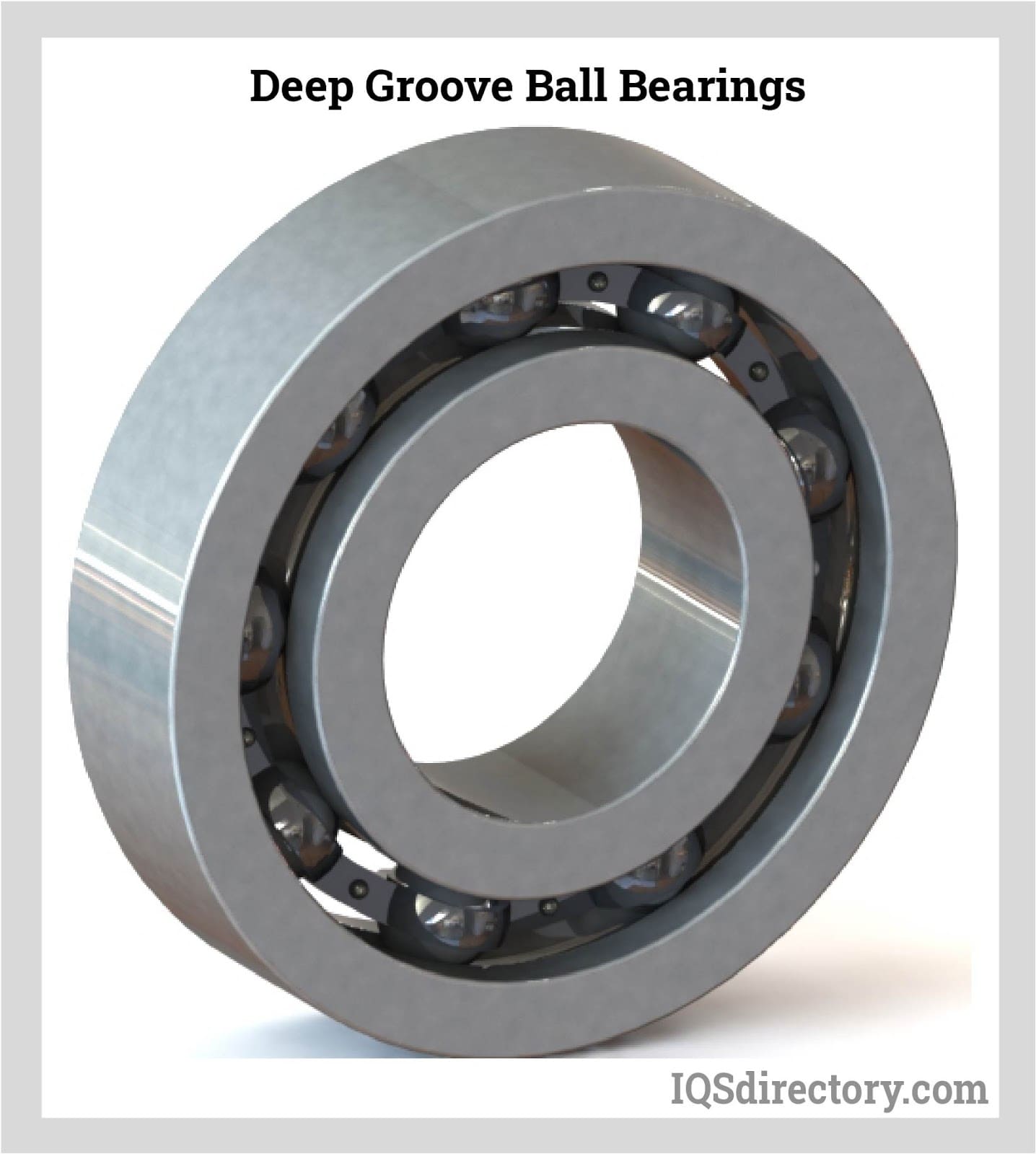

Rolling element bearings contain small balls that rotate and travel along tracks, called raceways. The linear ball bearings provide smooth, low friction movement that is repeatable, rigid and accurate. Plane bearings do not employ spherical elements and instead bring surface areas into contact with each other, requiring smooth surfaces and lubrication. Plastic linear bearings are available in the same configurations. Bearing housings and carriages made of plastic are increasingly common, but plastic ball bearings are also becoming important in certain applications.

Plastic ball bearings offer high acceleration speeds, quick start-and-stop abilities and increased resistance to damage and wear over time. Plastic bearings that slide without the use of rolling elements have similar benefits. Because there is no metal to metal contact involved with a plastic linear bearing, there is less friction and heat that would slow movement.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services