Linear motion bearings are motion components used to aid in low friction linear motion of loads requiring high accuracy and repeatability in their movement. Due to their accuracy, low cost, and availability, linear motion bearings are used in a variety of industrial applications. Read More…

With a multitude of bearing and slide designs available, both standard and custom designed models, Del-Tron Precision Inc. is proud to be a one-stop shopping experience for customers with linear motion needs.

TUSK Direct is a company that produces high quality linear motion components such as linear bearings as well as assemblies for automated equipment.

Isotech is a distributor of precision linear motion components -- crossed roller linear bearings, ball slide assemblies, crossed roller slide tables, motorized tables, position stages and more.

More Linear Motion Bearing Manufacturers

Bearing systems are typically low maintenance motion device options; however linear motion bearings will require periodical maintenance and/or replacing to ensure the optimum performance of the system.

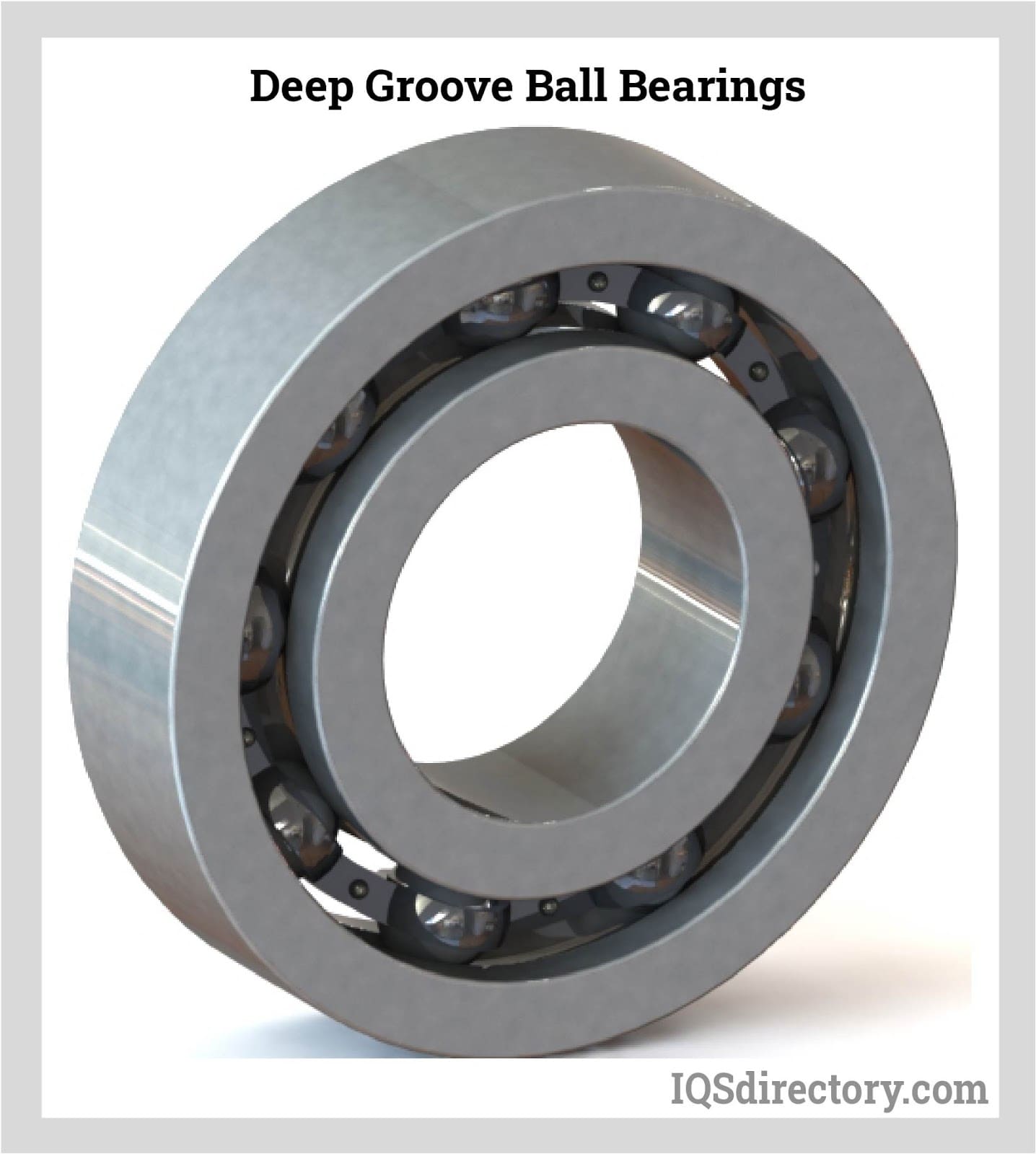

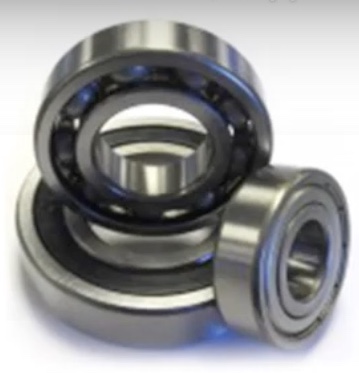

There is a wide range of styles of linear motion bearing devices such as linear air bearings, linear roller bearings, linear ball or rotary bearings and more. Rolling element linear motion bearings, of which linear ball bearings and linear roller bearings are varieties, are far more accurate than sliding contact bearings and so are among the most commonly used linear motion bearings.

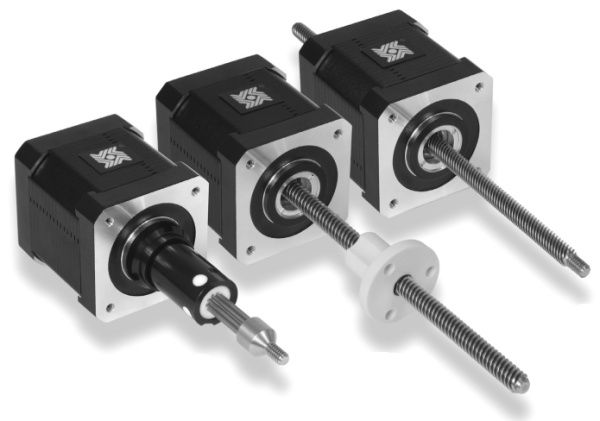

Linear bearing systems can vary in terms of stiffness or intended velocity, as well as in the smoothness of motion. These factors will be adjusted according to the application of the bearing slide.

Other factors such as height and length, rolling element and material choice can also be changed according to specific needs. Linear bearings are commonly constructed from materials like steel or aluminum which provide a strong and durable material able to bear the weight of moving loads without excessive wear and tear. Rolling elements are either ball bearings or roller slides. Ball bearings tend to wear out faster than roller slides, but both are useful in a wide variety of applications.

The load capacities of linear devices can vary greatly according to design and depending on the material used to construct the motion device. Motorized linear slides can be used for heavier loads or for extreme precision and are moved by drive mechanisms. Other manually operated slides rely on gravity, inertia or hand power to move.

For heavy load applications, or for long distance applications, the housing system of the linear motion bearings can be strengthened by the addition of support rails or guide wheels either continuously or at intermittent points in order to prevent structural failure along the linear rails.

Upkeep for linear motion bearings may include slight railing and positioning adjustments, especially in applications with heavy loads and/or those requiring high precision. For applications in which air-borne debris is a factor, the bearings and assembly shafts may have to be opened and cleaned. Lubricants can also be added to the rail systems to extend the lifespan of the bearings and to further minimize friction.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services