Flat pad air bearings are shaped like hockey pucks while others are of varying height, diameter and shape. Linear bearings are made from hardcoat aluminum, stainless steel, steel, granite, ceramic, bronze or carbon and are typically found in a rectangular housing of similar materials, mounted on a track for fast, smooth and precise motion. Read More...

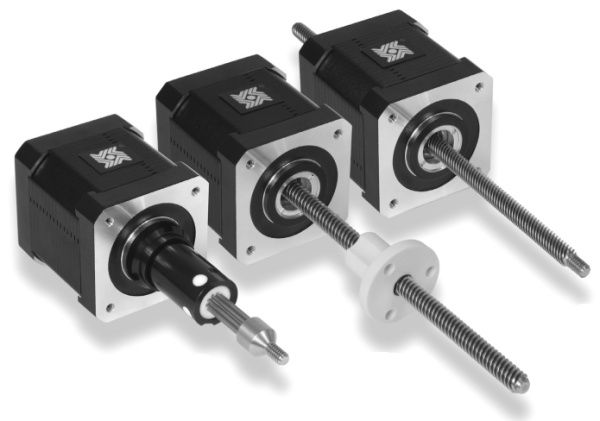

Ball & crossed roller slides, multi-axis positioning stages, motor-ready lead screw stages, air actuators, recirculating slide guides, crossed roller rail sets. Subminiature & heavy duty, straight line design & recirculating. Custom design available. Website life/load calculators CAD drawings. Our greatest strength is to offer components which provide a reliable mechanical interface for equipment.

Linear motion components, assemblies for automated equipment. Ball & crossed roller slides, linear bearings, economic linear bearings, Teflon linear bearings, multi-axis positioners, subminiature to heavy-duty, long travel available. Same-day ship, life-load calculators, CAD drawings. Call before noon & you will be working with your products the next day. We want TUSK to be the name you think of!

More Linear Air Bearing Manufacturers

Useful in a variety of applications, linear air bearings are found in the manufacturing, medical, research, chemical and engineering industries for precise assembly, force measurement, calibration, semiconductor pick-and-place machinery, zero-gravity simulators, scanning and more. Because they are free of oils or lubricants and rely on pressurized air, they are suitable for use in clean rooms.

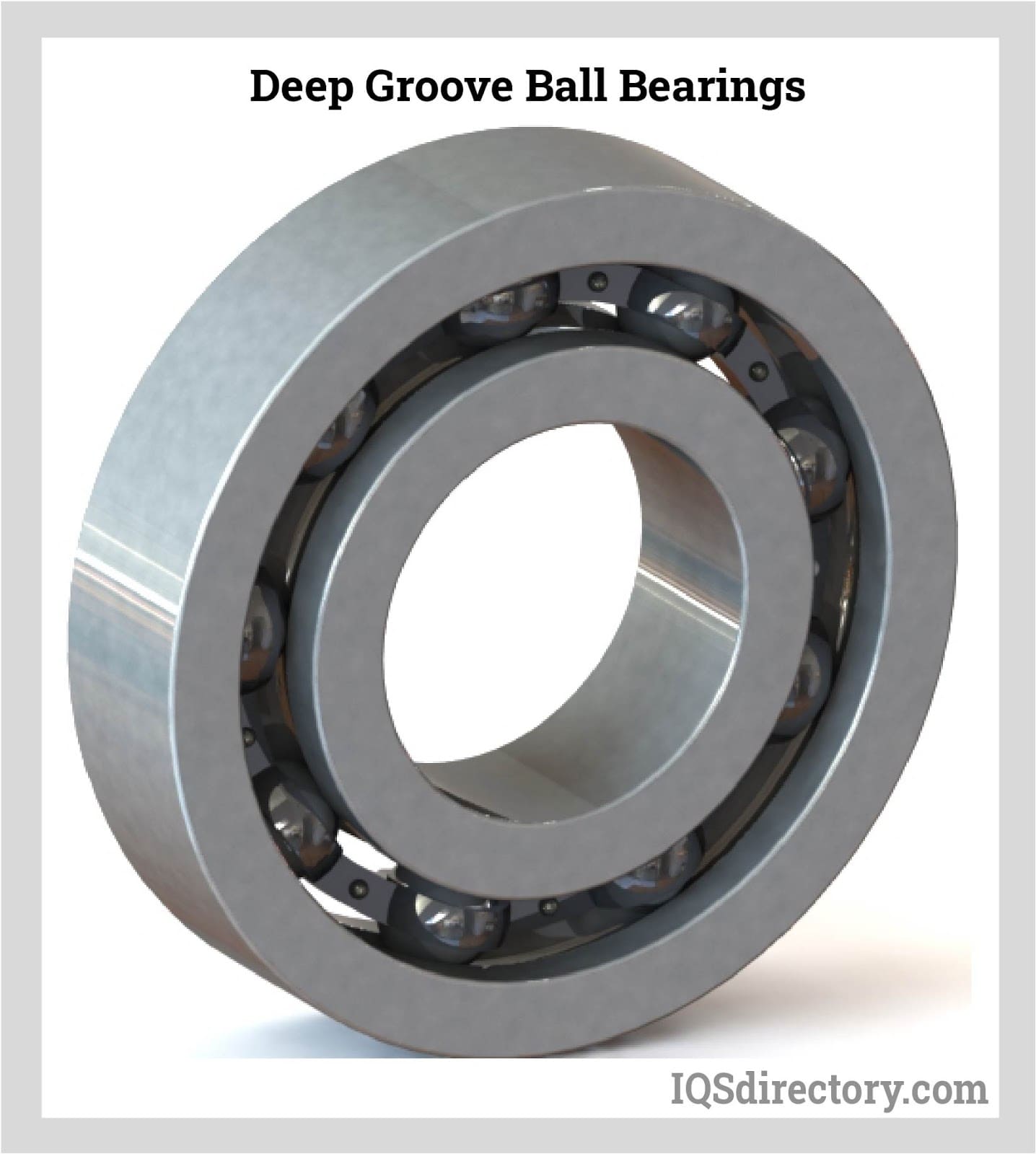

In order for fluid film bearings to work, they must have a source of pressurized air, though nitrogen can also be used. Hydrostatic bearings use an external pressurized supply while hydrodynamic bearings use the motion of the machine’s components to self-generate internal pressure. Typical bearings are hydrostatic and use simple compressed air to operate. The two main kinds of air bearings—porous and orifice—refer to how pressurized air enters the bearing.

Air penetrates through millions of tiny holes in the media of a porous bearing while an orifice bearing has a small hole fractions of an inch in diameter that air flows through. As air is steadily fed to the bearing, a layer only microns thick forms around the bearing, separating it from the surface and allowing the housing to glide smoothly and precisely.

Computers or machine operators control the movements of the machine; air bearings do not lose accuracy or shape and therefore only need to be calibrated once. Because they are frictionless, air bearings cannot overheat and will not warp or wear; they also do not need to warm up before the desired range of motion is achieved. Manufacturers do recommend, however, that the bearings are used in an environment that is at room temperature so the housing does not distort and disturb the layer of air around the bearing.

Air Cylinders

Air Cylinders Assembly Machinery

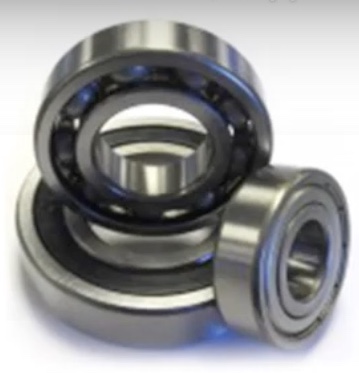

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services